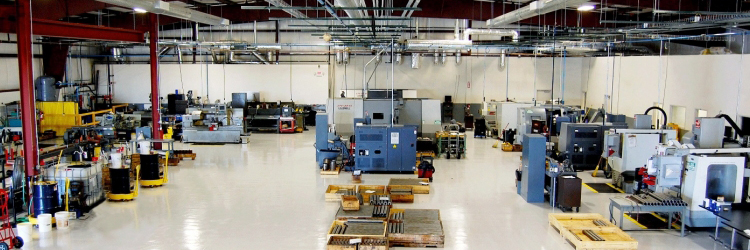

Core Competencies and Manufacturing facility

Core Competencies and Manufacturing facility

|

- Machinery:

We have a wide range of molding machines suited to different sizes and quantities. We mold small parts (a few millimeters in size) up to very large parts (700mm across and up to 10kgs in weight) and manufacture both in small quantities (10’s and 100’s off) and in very large quantities (millions).

The strength of TA international is its latest machinery and advanced Equipment.

Rubber Molding (100 TON -250 TON)

- CNC Rubber Injection Molding Machines

- Rubber Transfer

- PLC Compression Molding Machine

- CNC Rubber Oil Seal Hydraulic Compression Molding Machines,

Rubber mixing

- Rubber Kneader Mixing Machine

- 30 Inch Roller Mixer

Press Shop

- Hydraulic Presses

- Mechanical Power Presses

- Galvanizing Plant

- Electroplating Plant

- Hydraulic Shearing Machines

Welding shop

- MIG/MAG Welding Plants

- ARC Welding Plants

- Tool & Die shop

Not only the machinery is strength but these machines are operated by our multitalented technicians specially trained by internal and external Engineers. Our Engineers team is qualified by reputed institutions.

- Testing and Inspections

|

We have on-site technical teams for molds design, raw material formulation and development

Quality is often described as “fitness for purpose” but such a definition has no cost or processing considerations. A part produced using poor processes, which can be guaranteed only as the result of inspection, has no inherent quality. So, improving the quality standards TA international has generated quality control Department where our qualified polymer engineer do experiment on latest apparatus to check the material quality and his team do quality check while getting raw materials by the supplier and our engineers monitor production process all the time. When goods get ready then quality engineer put his stamp on it that ensures the customers satisfaction. |